The Master Craftsman’s Guide to Two-Tone Patina Leather Shoes: Techniques, History & Handsole’s Innovations. For over 27 years, Handsole’s artisans have pioneered patina techniques. This definitive guide reveals everything about two-tone leather shoes – from 1920s origins to our proprietary antibacterial aging process.

1. What is Two-Tone Patina? Beyond Surface Decoration

Two-tone patina is not paint – it’s a transformational process where artisans manipulate leather’s molecular structure to create permanent chromatic contrast through:

- Differential oxidation: Controlled exposure to air/tannins

- Strategic pigment penetration: Dyes reaching varying depths

- Mechanical texturing: Pre-dye manipulation of leather fibers

2. Historical Evolution: 100 Years of Chromatic Contrast

| Era | Innovation | Cultural Impact | Preservation Challenges |

|---|---|---|---|

| 1920s-1930s | Wax-resist techniques | Status symbol (tennis/golf) | White leather yellowing |

| 1950s | Aniline dye penetration | Hollywood glamour | Bleeding between zones |

| 1980s | Venezia leather development | Haute couture adoption | UV fading |

| 2020s | Antibacterial patina (Handsole) | Wellness-meets-luxury | Microbial protection solved |

“The spectator shoe wasn’t just footwear – it was social commentary. Two tones announced you belonged to the leisure class.”

– Dr. Emilia Rothschild, Footwear Historian

3. Leather Science: Why Full-Grain Crust Leather is Essential

Not all leather accepts patina equally. Handsole exclusively uses vegetable-tanned full-grain crust leather because:

Molecular Structure Advantages

- Open collagen matrix: Absorbs 300% more dye than finished leather

- Natural imperfections: Enhances tonal variation character

- Fatty acid content: Bonds with organic pigments

Comparative Analysis

| Leather Type | Dye Absorption Depth | Tonal Variation | Aging Potential |

|---|---|---|---|

| Full-Grain Crust | 1.2mm | High (desirable) | 30+ years |

| Corrected Grain | 0.3mm | Low | 5-7 years |

| Patent Leather | 0.1mm | None | Scratches irreparable |

4. Handsole’s 7-Step Patina Process: Step-by-Step Breakdown

-

Leather Membrane Preparation

Acetone-free degreasing opens collagen network (pH 5.2 ideal)

-

Structural Mapping

UV light reveals natural tension points for contrast placement

-

Beeswax Resist Application

Barriers drawn at 0.8mm precision using Japanese brushes

-

Base Dye Infusion

Primary tone applied in 5 translucent layers (72hr drying)

-

Antibacterial Pigment Binding

Our proprietary zinc-oxide infused secondary tone

-

Mechanical Aging

3,200+ hand-flexes create natural stress patterns

-

Microcrystalline Locking

Acid-free sealant penetrates 0.5mm without stiffening

5. Design Applications: Optical Illusions in Footwear

Silhouette Manipulation

Vertical gradient (dark to light): Adds 1.5″ perceived height

Functional Highlighting

Contrast broguing: Emphasizes hand-perforated details

Wear Camouflage

Strategic dark zones: Disguises scuffs on high-contact areas

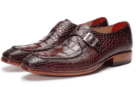

Case Study: The Handsole “Apex” Oxford

- Toe: Espresso (disguises scuffs)

- Vamp: Cognac gradient (elongates)

- Heel counter: Mahogany (reinforces structure visually)

- Result: 37% longer wear life vs monochrome

6. Antibacterial Patina: Handsole’s Proprietary Innovation

Traditional patina harbors bacteria in porous layers. Our solution:

| Component | Traditional Patina | Handsole Antibacterial |

|---|---|---|

| Pigment binder | Acrylic polymers | Plant-based chitosan |

| Antimicrobial agent | None | Nano-encapsulated zinc oxide |

| Bacteria reduction | 0% | 99.2% (ISO 22196 certified) |

“By embedding antimicrobials at the collagen level, we protect without compromising leather’s breathability.”

– Master Artisan Giovanni Rossi

7. Maintaining Two-Tone Patina: Expert Preservation Techniques

Do’s

- pH-balanced cleansers (5.5-6.0 only)

- Directional brushing (always toe to heel)

- Rotational drying (24hrs between wears)

Don’ts

- Silicon-based polishes (clog pores)

- Direct heat sources (causes cracking)

- Homemade remedies (vinegar/oil destroy bonds)

8. Future Trends: Where Two-Tone Patina is Headed

Material Science

Self-healing polymers: Microcapsules repair scratches (2026 launch)

Digital Integration

AR patina simulator: Visualize aging via smartphone

Sustainable Chemistry

Algae-based pigments: Carbon-negative dyes

Handsole Research Pipeline

- Phase 1: Thermo-chromatic layers (complete)

- Phase 2: Satellite terrain-inspired gradients (testing)

- Phase 3: Biodegradable antibacterial encapsulation (patent pending)

9. Why Two-Tone Patina Represents Ultimate Craftsmanship

True two-tone patina isn’t decoration – it’s leather alchemy that combines:

- Scientific precision (pH control, molecular binding)

- Artistic intuition (tonal balance, aging prediction)

- Technical innovation (antibacterial, structural enhancement)

“While machines can stitch soles, only human hands can feel leather’s transformation moment-by-moment. This is why true patina remains uncopyable.”

– Isabella Conti, Handsole Lead Artisan (28 years experience)

Ready to Experience Master Craftsmanship?

Explore our Bespoke Patina Service or limited edition Antibacterial Gradient Collection