Introduction

Hand-dyeing leather is more than just a craft—it’s a form of artistic expression that transforms raw material into a truly one-of-a-kind product. Whether you’re a leatherworker, designer, or just a curious reader, understanding how dyes interact with leather can open up a world of customization. And no, we’re not talking about dipping leather in a vat of random color and hoping for the best—there’s a method to the madness (well, usually!).

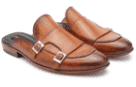

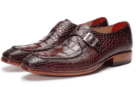

In this article, we’ll explore the ins and outs of hand-dyeing leather—from traditional brush techniques to modern sponge applications. We’ll look at the benefits too: from creating stunning color gradients to enhancing the leather’s natural grain. So if you’ve ever wondered how artisans get those rich, layered tones on wallets, shoes, or belts—yep, this is the article for you. Buckle up (pun intended), we’re going to make dyeing leather sound a lot more fun than it probably should.

Key Takeaways

Hand-dyeing leather offers custom color control and rich, layered finishes.

Various techniques like sponge, dauber, and brush allow different artistic effects.

Better absorption means deeper color penetration and long-lasting results.

Natural leather grain is enhanced, not hidden, during hand-dyeing.

Ideal for small-batch artisans and luxury goods with unique finishes.

Techniques and Tools for Hand-Dyeing Leather

Hand-dyeing leather combines skill, patience, and the right tools. Unlike factory-dyed leather, this approach lets you manipulate every layer of color by hand, giving each piece its own character. It’s a favorite among custom leatherworkers, especially those focused on artisanal or luxury goods.

A few essential tools are commonly used. Daubers, sponges, and soft brushes help control dye application, while wool pads and airbrushes offer more advanced techniques. Each tool delivers a unique finish, from smooth gradients to rugged, vintage patinas. Prepping the leather is crucial—this means cleaning and sometimes lightly sanding the surface to help the dye absorb evenly. The dye itself ranges from alcohol-based (fast drying, vivid colors) to water-based (eco-friendlier, slower drying).

Experimentation is part of the fun—and the learning curve. It’s not unusual to mess up the first few times (been there!), but the payoff is a piece of leather art that looks nothing like what rolls off a factory line.

Sponge and Dauber Application

Sponge and dauber dyeing are two of the most popular hand techniques, especially for beginners. Sponges allow for broad, even coverage and are excellent for layering colors or blending gradients. They’re great for applying dye in circular motions, which helps avoid streaks and patchiness. Just watch the pressure—you don’t want to oversaturate the leather.

Daubers, often made from wool or foam, are small and precise. They’re great for detailed areas or edging where you need control over how much dye you’re applying. These tools work well with alcohol-based dyes because they dry quickly and can be layered for depth.

Both tools offer a lot of flexibility, and when used together, they let you create effects that range from bold, solid color blocks to soft ombré fades. Keep a scrap piece nearby—always test before committing to the final surface!

Brush and Airbrush Techniques

Using a brush to hand-dye leather offers precision and control, especially useful for intricate patterns or hand-painted designs. Brushes allow artisans to work pigment into creases, tooling details, or around stitching with accuracy. They come in all sizes—flat brushes for coverage, round ones for detail—and work best with water-based or gel dyes, which don’t dry as fast as alcohol-based ones.

Airbrushing, on the other hand, is like the Ferrari of hand-dyeing techniques. It requires more setup (and practice), but the results? Chef’s kiss. You can apply ultra-thin layers of dye, achieving a smooth, flawless gradient or rich saturation without brush marks. It’s ideal for large surfaces or creating complex shading.

That said, airbrushing needs ventilation, consistent hand motion, and a bit of finesse. It’s not the go-to for leather beginners, but once mastered, it delivers a clean, professional finish that’s hard to beat with manual tools. Just don’t forget the mask—safety first, always.

Benefits of Hand-Dyeing Leather

Hand-dyeing leather doesn’t just look cool—it unlocks a host of practical and aesthetic advantages. Whether you’re crafting a luxury wallet or restoring an old pair of boots, the control and customization it offers can dramatically elevate the final product. It’s a technique that allows artisans to connect with their work on a deeper level, producing leather items that are as expressive as they are functional.

One major perk? Custom coloration. Unlike pre-dyed leather, you’re not stuck with standard hues. You can match any color palette or even replicate natural finishes like sun-tanned brown or antique patina. Beyond looks, hand-dyeing enhances the tactile qualities of leather, preserving its natural grain and feel rather than masking it with heavy coatings. That’s a big win in terms of both aesthetics and quality.

Plus, it often extends the life of the product. Since you’re working dye into the leather fibers rather than applying a surface pigment, the color tends to age more gracefully—no peeling or cracking, just a rich patina over time.

Customization and Artistic Expression

Perhaps the most exciting benefit of hand-dyeing is the sheer creative freedom it offers. You’re not limited to factory-finish browns or blacks—you can blend, layer, fade, or distress colors to your heart’s content. Want a vibrant crimson fade on your belt? Or a distressed teal on your journal cover? You got it.

This level of customization is especially valuable for small-scale artisans or boutique brands that rely on uniqueness as a selling point. Hand-dyeing makes it easy to offer customers something they won’t find on store shelves. It also opens up opportunities for personal expression: initials, symbols, even art can be incorporated into the dyeing process.

For hobbyists, it’s incredibly satisfying. There’s something rewarding about seeing your vision go from a raw hide to a fully-colored, ready-to-use piece—imperfections and all. Those little mistakes? They often become part of the charm.

Enhanced Durability and Longevity

Hand-dyeing also scores points in the durability department. When done correctly, the dye penetrates deep into the leather fibers rather than just sitting on the surface. That means the color won’t flake or crack over time, even with regular use or exposure to moisture and sunlight.

This makes hand-dyed leather ideal for everyday carry items—think wallets, belts, bags, or even footwear linings. Because the dye is absorbed, it moves with the leather as it flexes and bends, reducing the risk of surface wear. Alcohol- and oil-based dyes tend to perform best for long-term resilience, especially when paired with a quality leather conditioner or sealer.

In short, the end product isn’t just prettier—it’s tougher too. That makes hand-dyeing not just an artistic choice, but a smart investment in the lifespan of your leather goods.

Conclusion

Hand-dyeing leather is where craftsmanship meets creativity. It transforms an ordinary hide into a piece of functional art, with each brushstroke or dauber dab telling its own story. Whether you’re using sponge techniques for bold coverage or airbrushing for that buttery smooth gradient, the possibilities are nearly endless—and deeply personal.

What really sets hand-dyeing apart is the balance it strikes between form and function. You get custom color control, longer-lasting results, and the satisfaction of creating something truly unique. So whether you’re a weekend hobbyist or a seasoned leather artisan, hand-dyeing is a skill worth exploring. Go ahead—dye with passion, not just purpose.

FAQs

What type of leather is best for hand-dyeing?

Vegetable-tanned leather is ideal because it absorbs dye evenly and responds well to layering techniques. It also has minimal surface treatments that could interfere with dye absorption.

Can I hand-dye chrome-tanned leather?

Technically yes, but it’s not recommended. Chrome-tanned leather usually has a finish that resists dye, making the color uneven and unpredictable. Stick with veg-tan for the best results.

Do I need to seal hand-dyed leather?

Yes! After dyeing, always apply a leather sealer or finish to protect the color, lock in moisture, and prevent fading or rubbing off. Think of it as the topcoat to your leather masterpiece.

Is hand-dyeing waterproof?

The dye itself isn’t waterproof, and neither is leather by default. You’ll need to apply a water-resistant finish or wax if the item will be exposed to moisture regularly.

How long does it take for hand-dyed leather to dry?

Drying time varies by dye type. Alcohol-based dyes dry in 15–30 minutes, while water-based ones can take several hours. Always let it cure fully before sealing or handling heavily.

Hand-Patina Leather Finish Techniques

Welting: A Brief Guide to Shoe Construction