Dive Deep in to our leather shoe making process

Follow our journey of transforming full-grain leather into beautifully handcrafted Shoes through hand-welting, hand-lasting, and hand-dyeing. See how we handcraft each shoe with care, ensuring authenticity and transparency in our production process. Join us in our honest production process.

The Last Comes First . Select Last

From planning to finishing, the shoe last plays a vital role in defining the size, silhouette, and overall outline of our custom handmade leather shoes. Each shoe last is meticulously crafted to fit precise measurements, including shoe size, sole shape, width, and arch support, ensuring that every pair achieves the perfect fit.

Our custom shoe molds and high-quality leather are the foundation of our bespoke craftsmanship, aligning with traditional shoemaking techniques to shape shoes that not only meet fashion trends but also offer lasting comfort.

#ShoeLasts #FootwearDesign #ShoeCraftsmanship #ShoeDesign #ShoeMaking

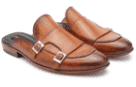

Choose the Right Leather

The heart of our hand-lasted, hand-welted leather shoes starts with selecting the best leather. Our Master Upperman carefully picks each hide for its softness and quality, knowing it shapes the final look of the shoe. Thicker leathers provide strong support for Oxfords, while softer leathers allow for a sleek design in loafers. This balance between leather type and shoe style ensures a perfect fit and comfort for your feet.

From leather selection to the next step, designing a custom shoe pattern, we create footwear that perfectly reflects your unique style.

#LeatherSelection #CraftsmanshipStartsHere #MaterialSelection. #LeatherQualityMatters

Create Custom Shoe Pattern

This is where creativity meets precision, as we transform high-quality leather into a beautifully crafted shoe. Our pattern master carefully creates a blueprint that guides the cutting and stitching of the leather.

This process involves thorough planning for features like arch support and toe room, which are essential for a perfect fit. With a focus on handcrafted quality, we blend traditional techniques with modern innovations to create patterns that reflect your unique style. This thoughtful approach results in footwear that is both fashionable and functional, ready to make a statement with every step.

#HandmadeShoes #PatternCrafting #ShoemakingArtistry #CustomFootwear

Hand-Cut leather for Custom Fit

With the shoe pattern in place, we move on to the crucial step of cutting leather to pattern. Here, our attention to detail truly shines. While many manufacturers rely on machines, we hand cut each piece to ensure precision and control, resulting in a superior fit that eliminates painful break-in periods.

This careful approach means our shoes provide immediate comfort and support, addressing common issues like inadequate fit and discomfort.

We create shoes that are not only stylish but also practical, making sure every pair is ready to support you throughout your day.

#Leather Patterns #LeatherArt #ArtisanSkills #HandcraftedLeather #CraftsmanshipMatters

Stitch Leather: Create Upper

Here, the artistry truly comes to life. Our artisans prepare each piece of leather, carefully considering how every stitch will enhance the shoe's durability and comfort. This process is not just about joining materials; it’s about creating a harmonious fit that feels like a second skin.

Every stitch is placed with purpose, ensuring that the upper hugs the foot perfectly while adding a distinctive touch of style. This attention to detail transforms a simple upper into a masterpiece, ready to take on the world. The commitment to quality stitching is what elevates our shoes, giving them character and resilience that sets them apart.

#LeatherUpperStitching #CraftedLeatherUppers

Attach Handmade leather insoles to the last

With the midsole and insole carefully crafted, the next step is attaching these leather layers to the last, where the real magic of shaping happens. By securing the midsole and insole by hand, each piece is precisely aligned, ensuring they mold perfectly to the foot's natural form.

This attention to detail reinforces the shoe’s foundation and creates a fit that only improves with wear. It’s not just about putting pieces together; it’s about creating a shoe that feels like an extension of you, from the first step to the thousandth.

#CustomInsoles #FootSupport #HealthyFeet #FootHealth #OrthopedicInsoles #ArchSupport #HappyFeet #WalkInComfort

Hand Last = Pure Perfection

After securing the midsole and insole, we move to hand-lasting—where the shoe truly takes shape. During this step, the leather upper is carefully stretched and molded over the last, ensuring every curve hugs the foot just right. Hand-lasting allows us to make micro-adjustments, so the leather aligns perfectly to eliminate pressure points and enhance support where it matters most. The lasted upper rests on the last for 24 - 48 hours to further mold to its shape.

For you, this means a shoe that not only feels natural but adapts to your movement, minimizing discomfort and providing a consistent fit.

#GenuineCraftsmanship #HandcraftedShoes #ArtisanFootwear #TraditionalCraft #HandmadeLuxury

Hand-Welting for Lasting Bond

With the hand-welting process underway, we begin stitching the upper, midsole, and insole together by hand. This technique delivers a level of craftsmanship and durability that machine-made or Goodyear-welted shoes simply can't match. While Goodyear relies on machines for speed, hand-welting allows us to control each stitch’s tension and alignment, resulting in a stronger bond that withstands years of wear. This approach creates a personalized fit that adapts to your feet over time.

For you, this means a shoe that molds to your feet, providing exceptional comfort and quality—truly a difference between mass-produced footwear and a carefully crafted piece designed to last.

#GenuineCraftsmanship #HandcraftedShoes #ArtisanFootwear #TraditionalCraft #HandmadeLuxury

Making the Heel: Stacked Leather

With the hand-welting complete, we now turn to crafting the heel using stacked leather, chosen for its durability, flexibility, and comfort. Unlike traditional wooden or fiber heels that can crack or wear down over time, stacked leather creates a strong yet adaptable foundation that molds to your movement. This technique layers strips of leather, bonding them together to form a heel that’s not only sturdy but also refined in appearance. This ensures the heel maintains its shape and integrity, giving you consistent support with every step. For you, this means a heel built to withstand daily wear, offering superior comfort, stability, and longevity—making each pair an investment in true craftsmanship.

#HandmadeLeatherHeel #LeatherStacks #CraftedWithPrecision #ShoeCraftsmanship #ArtOfShoemaking

Sanding & Shaping Sole & Heel

With the hand-welting complete, we move on to hand-cutting and shaping the outsole—the final layer that connects you to the ground. Here, we use high-quality leather and cut it by hand to match the exact contours of the shoe, ensuring a snug, seamless fit with the midsole.

Hand-shaping the outsole provides flexibility and allows us to fine-tune the thickness and texture to give you a stable, comfortable foundation. Unlike machine-cut outsoles, which are often rigid and uniform, a hand-shaped leather outsole adapts over time, molding to the way you walk and adding a level of natural grip and resilience.

For you, this means a shoe that not only lasts longer but feels more natural with every step. It’s not just footwear—it’s craftsmanship you can feel from heel to toe.

#HandMade LEather shoes # Mirror SHINE SHOE SOLE

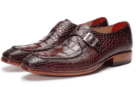

Finishing and Hand Patina

With the heel attached and finishing sanding complete, we turn to the final step: applying a hand patina. This technique enhances the shoe’s appearance and provides lasting protection. Using dyes and oils, the hand patina creates rich, unique tones that develop character over time, unlike uniform machine finishes. For you, this means shoes that age gracefully, combining exceptional looks with durability. The patina allows the leather to breathe, ensuring comfort and making each pair a true expression of craftsmanship and individuality.

#GenuineCraftsmanship #HandcraftedShoes #ArtisanFootwear #TraditionalCraft #HandmadeLuxury